Death to class H. Long live DELFIRE

An H class motor is not a DELFIRE. An H class is not a real solution to high ambient temperatures

At Motive, we also had H class, but we cancelled it from the configurator because it had not much sense when you want to give to the client what he really wants. Let's give an explanation:

The difference between a standard F class motor and the H class, is the max temperature of the insulation material (155°C for F or 180°C for H). The insulation material is the slot insulation and the the one of the copper wire insulating enamel

There is only one reason why a client may ask for an “H Class” motor: the ambient temperature (theoretically 40°C of max amb temp of the F class, while 40°C+180°C-155°C=max 65°C for an H class). Here we see a first difference: DELFIRE is for up to 100°C.

However, 65°C of max amb. temp. for an H class IS just THEORY!

IN PRACTICE, is an H class motor really designed to be suitable for an higher temperature ambient? The norm says NO!

The norm says that an H class motor is also designed for an ambient of 40°C, like the F class. See page 25 of our DELPHI catalogue

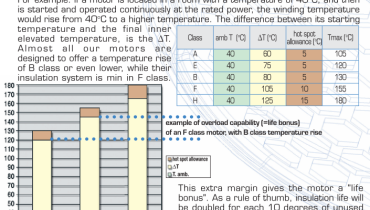

In fact, as you can see in the graph, an H class motor is also permitted to have an internal higher temperature rise "Delta T" (for example due to a lower efficiency). Such allowed higher Delta T of an H class motor can compensate and cancel the advantage of the higher insulation burning temperature. Actually, therefore, the client should also know the temperature rise of the motor, but we do not know anyone that, unlike motive, declares such Delta T of each motor rating in its catalogues.

But if motive declares its temperature rise, so, why doesn’t motive recommend H class? Because, if you want to install a motor in a higher temperature ambient, knowing that the motor has an H class insulation and that the temperature rise is low, is not enough. In fact, what about the bearings? Can they face an higher temperature? What about all plastic parts like fan, fan cover, cable gland? Can they deteriorate due to that temperature? What about the thermal dilatations? Can they create problems? What about the NBR oil seals, that should not exceed 100°C? (here, it’s not the ambient temperature that matters, since the motor heat has to be added onto it). What about the temperature excursions and the the internal humidityr condensation on the electric winding?

Probably, while you were following me, you found that the solution to each of such problems is in DELFIRE, not in the H class insulation.

Adding higher efficiencies and defluxed coils, DELFIRE internal temp rise is further lowered.

RESULT? An H class is not sure that will not die at 65°C of Ambient temperature, while DELFIRE is sure that can work for a long life in 100°C ambient temperature