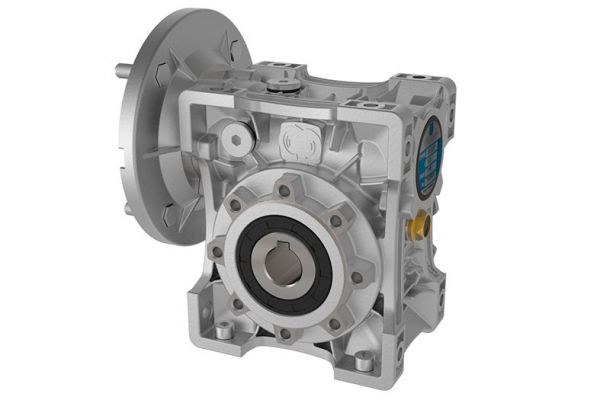

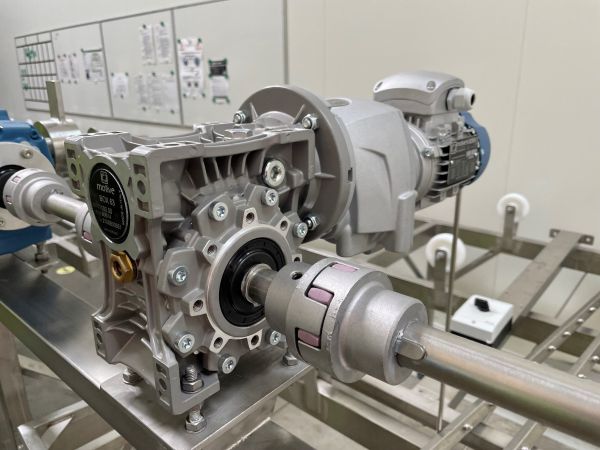

The new patented “BOX” series of worm gear units is made with die-casting aluminium housing from size 25 up to 90, and in cast iron from size 110.

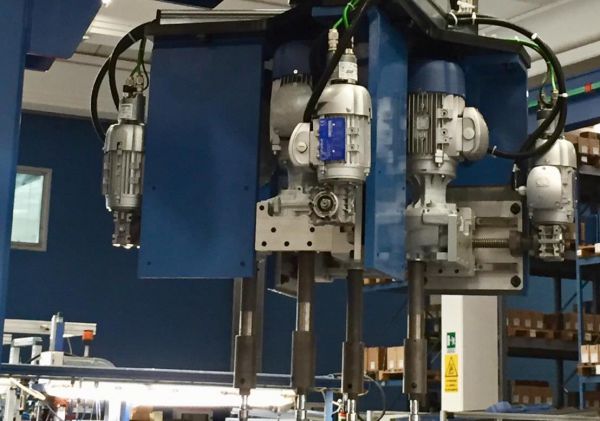

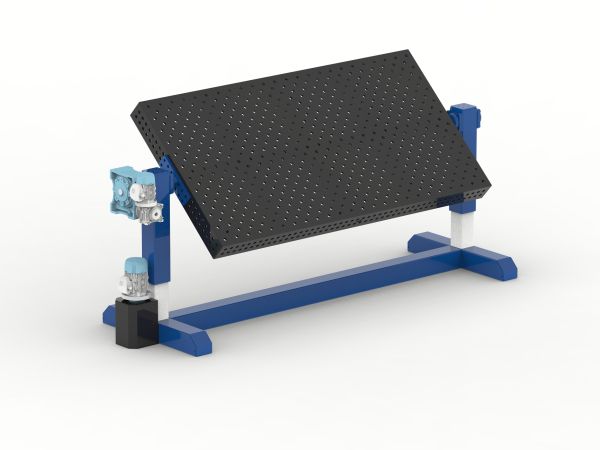

The whole BOX series can be mounted in any position with no need of specifications in the order

| BOX | motor type | max Nm (4 poles) |

| 25 | 56 | 13 |

| 30 | 56-63 | 19 |

| 40 | 63-71 | 39 |

| 50 | 63-71-80 | 74 |

| 63 | 71-80-90 | 135 |

| 75 | 80-90-100-112 | 205 |

| 90 | 80-90-100-112 | 360 |

| 110 | 90-100-112-132 | 675 |

| 130 | 90-100-112-132 | 850 |

| 150 | 100-112-132-160 | 1200 |

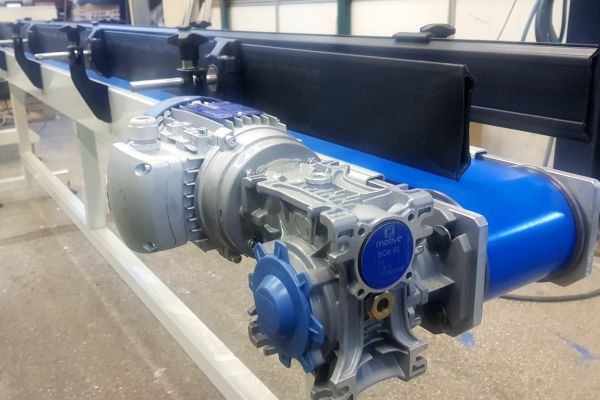

From type 75 and up, 2 taper roller bearings are mounted on the wormshaft, improving the mechanical resistance to the axial loads given by the wormwheel. Moreover, the combination of this characteristic and 2 nilos (mounted on size 75 and up to keep lubrication grease inside the bearings even when they are not touched by the oil bath), or, in alternative, special RS shields on such taper bearings, permits the mounting of the whole BOX range, from the size 25 to the size 150, in the positions V5 and V6 without any need of additional interventions.

The new patented “BOX” series of worm gear units is made with diecasting aluminium housing from size 25 up to 90, and in cast iron from size 110. The housing has been designed with parametric three-dimensional CAD SW supported by programs of analysis of the thermal dissipation capacity and the structural resistance/deformation under the effect of working loads.

Mounting positions B6 or B7 are also permitted on all the BOX series, thanks to the adoption of 2RS autolubricated bearings on the output gear. In conclusion, the whole BOX series can be mounted in any position with no need of specifications in the order.

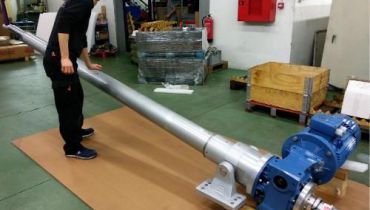

The housing shape has been studied to optimize the water draining during washing.

Lubrication is already provided by motive with long-life synthetic oil up to size BOX90, and with mineral oil from size BOX110. The gear unit is equipped with a full set of filler, level and breather plugs, permitting all mounting positions and facilitating the management of the stock.

In order to increase silence, efficiency and duration, the wormshaft is made in case hardened steel and ground machined, while the worm wheel is in shell cast ZCuSn12 bronze. The standard worm wheel hub is in spheroidal cast iron, an alloy that offers superior performance to grey cast iron and is suited also to heavy-duty use

An epoxy paint coat cancels the negative effects of the aluminium porosity and protects the housing from oxidation.

Mating surfaces are machined for a perfect planarity.

Instrukcja obsługi

Katalogi

Pobierz: BOX worm gearboxes Pobierz: NEMA BOX SERIES WORMGEAR UNITS Pobierz: Katalog ogólny

Altri Link

Zamówienia online: Zamówienia online